News

Special systems for every need and Industry 4.0

Special systems for every need and Industry 4.0 Special systems for every need and Industry 4.0 Special systems for every need and Industry 4.0 Special systems for every need and Industry 4.0 Special systems for every need and Industry 4.0 Special systems for every need and Industry 4.0 In order to best satisfy all customer …

Surface finishing, grinding and cleaning systems

Surface finishing, grinding and cleaning systems Apes Srl is a highly experienced company, present in both the Italian and international markets. We have always dealt with the design, construction and supply of industrial systems and automation and in this article we will provide you with some more information on our systems for sheet metal and …

Welding systems: how we work

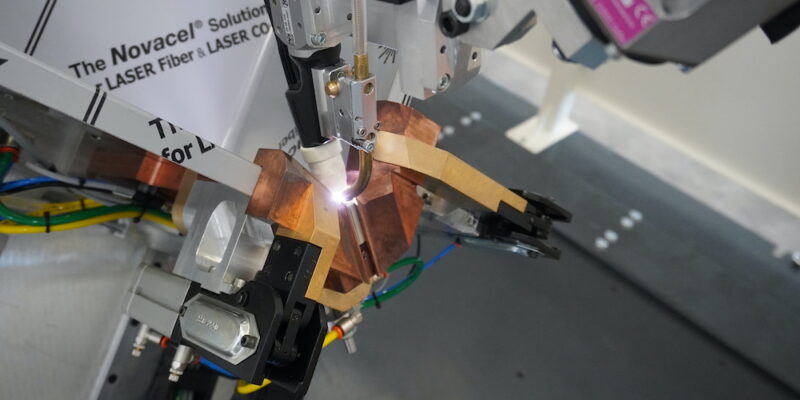

Welding systems: how we work Apes is a reality active in the Italian and international market for the supply of industrial systems and automations. In this article you can find out more about our work in the construction of welding systems.Our staff dedicated to design is always at the customer’s side in choosing the right …

Robotized areas: all the advantages

Robotized areas: all the advantages Apes Srl proposes the design and construction of entire automatic production lines or separate robotized areas: these are machines that are located inside an automatic work cell where programmable robots operate. Robotized areas can be implemented in different industrial sectors and optimize production processes to obtain high quality products. They …

Plant design: what it is and how to do it

Plant design: what it is and how to do it Plant design: what it is and how to do it Plant design: what it is and how to do it Apes Srl offers its customers many years of experience in the industrial automation sector. We represent a valid point of reference for companies in the …

APES: THE FAMOUS ROBOTIC ISLANDS IN THE WORLD.

APES: THE FAMOUS ROBOTIC ISLANDS IN THE WORLD. Apes is the brand that has always stood out in the specific market of competence for the design and construction of robotic cells built “to customer measure”. Robotic islands are processing areas made up of a set of industrial robots. The use of these separate production areas …